Performs enhanced real-time tracking of pipeline maintenance devices, so called pipeline pigs.

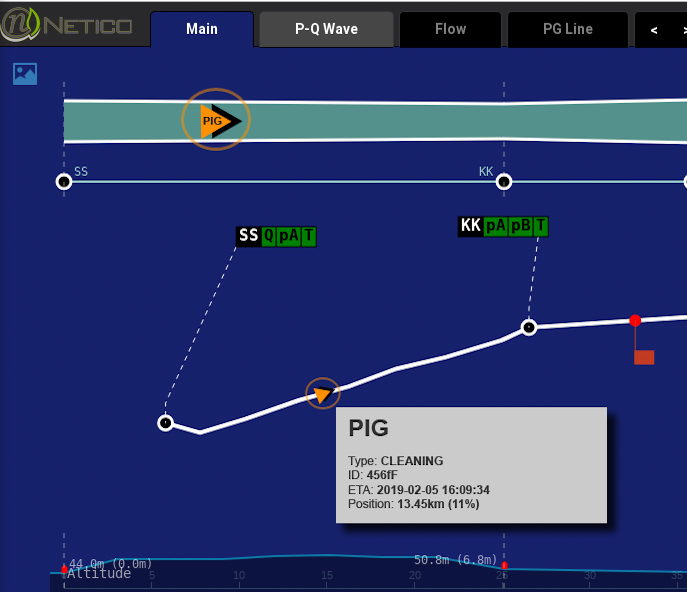

Netico's Pig Tracker is an application which tracks pipeline service devices (pigs) traveling down the pipeline. The Pig Tracker outputs information about the pig including: position, estimated time of arrival, velocity, slippage factor and more. It supports pipeline maintenance operations management by helping operators schedule pipeline maintenance activities and coordinate them with normal pipeline operations. In addition to this, Pig Tracker can help prevent asset damage by detecting stuck pigs and generating appropriate alarms related to the current pig status.

Main Features:

• Determines real-time pig position;

• Estimates time of arrival;

• Provides real-time velocity of pigs;

• Capable of tracking multiple pigs;

• Calculates real-time volume behind and in front of the pig;

• Unsusceptible to pipeline condition changes;

• Effective for bidirectional pipelines;

• Tracks different pig types;

• Data archiving;

• Detects and locate stuck pigs;

• Has an integrated alarm system;

Improved tracking algorithm

Pig Tracker uses an advanced algorithm, based on flow measurements and pipeline properties, and aimed at accurate tracking of pigs in the pipeline. The algorithm calculates the distance the pig has passed according to the current flow velocity, corrected by the slippage factor. Furthermore, the application estimates the arrival time at the destination facility or any other point ahead of the particular pig.

After the first pig run and the commissioning, the system continuously improves the estimation accuracy of the arrival time and traveled distance. The application uses pig passage indicator signals and archived data about velocity dynamics of previous pig runs to automatically adjust slippage factor and make more accurate future estimates. Additionally, Pig Tracker considers pressure measurements, fluid dynamic and composition, as well as real-time transient model to further improve the output accuracy, even during changes to the operating conditions.

Data archiving

Pig Tracker stores all key data about each and every pig run, including the following: launch/arrival time, pig route, pig velocity, slippage factor, passage detections, and any user interaction. Operators can hence generate various reports of past pig runs, by retrieving the data of interest. Slippage factor reports are particularly useful for comparison and review of parameters of current and past pig runs, to update the pig velocity slippage factor if necessary.

Seamless integration

Pig Tracker is developed to be used primarily as an optional module of Netico’s leak detection solution, Leak Hunter. However, it can be delivered as a stand-alone application or paired with the Batch Tracker solution. It integrates seamlessly with Leak Hunter and/or Batch Tracker systems and it is possible to integrate it into existing pipeline SCADA systems if necessary, to display pig information within existing SCADA views.

Intuitive user interface

Pig Tracker provides a user-friendly interface and an intuitive dashboard for easy tracking of pigs in the pipeline. Operators have a crystal clear visual presentation of all relevant information about every active pig traveling in the pipeline, with included real-time updates on position, velocity and estimated arrival times.

Integrated alarm system

Pig Tracker has an advanced alarm system intended to notify the operator of pig arrivals, forthcoming pig launches, and stuck pigs. Arrival alarm is configurable according to the estimated time of arrival, pig’s distance from the destination, or calculated volume behind and ahead of the pig. Operator can also define the thresholds and manually trigger alarms if necessary.

Immediately after detecting any stuck pig in the pipeline the application provides an appropriate alarm and pig’s location, which can help plan actions and prevent asset damage.

Related Case Studies

TRANSNAFTA

Transnafta uses Leak Hunter to achieve a secure and reliable transport of crude oil via pipeline.

Find Out More